About the Project

We’ve developed a large-scale educational cloud chamber (20×15×10 cm) that visually reveals natural radiation in real-time. Using four double-stage Peltier cells, the system cools the alcohol-air mixture down to -35 °C, creating the conditions needed to observe particle tracks with the naked eye. One of the largest of its kind worldwide. We built it to display in the Young Exhibition at Lariofiere, Italy, where it will be used to teach students about radiation and particle physics.

-

Date

October 2023

Nuclear Instruments

Young Exhibition

Lariofiere

Introduction: Seeing the Invisible

Radiation is all around us, yet it’s invisible to our senses. One of the most captivating ways to make it visible is through a cloud chamber — a device that reveals the paths of subatomic particles as delicate trails of condensation. Originally invented in the early 20th century, cloud chambers have been used to discover particles, study cosmic rays, and teach physics. Our project brings this fascinating device into the classroom and exhibition hall with a uniquely large and effective design.

The Theory: How a Cloud Chamber Works

A cloud chamber operates on a simple but powerful principle. A supersaturated vapor — typically alcohol — is cooled near its condensation point. When a charged particle (like an alpha or beta particle) passes through the vapor, it ionizes the gas along its path. These ions act as nucleation sites, triggering the condensation of alcohol into tiny droplets. The result is a visible track that mirrors the particle’s trajectory in real time.

There are two main types of cloud chambers:

-

Diffusion cloud chambers, which rely on a temperature gradient (cold bottom, warm top) to maintain a supersaturated layer.

-

Expansion cloud chambers, which use a sudden pressure drop to achieve supersaturation.

Our design is a diffusion-type chamber, chosen for its ability to continuously show radiation without the need for mechanical components or active cycling.

Design Overview: A Large Educational Device

Our goal was to create an educational cloud chamber large enough to allow clear, eye-level viewing of radiation tracks by groups of people — students, educators, or museum visitors. Most commercially available chambers are compact and require dark rooms or cameras for proper visualization. We wanted to go further: a visible, impressive, and robust demonstration tool.

The active volume of our chamber measures approximately 20 × 15 × 10 cm, making it one of the largest operating cloud chambers available for public education. This generous volume enhances visibility and increases the chance of spotting natural background radiation or particles from small radioactive sources.

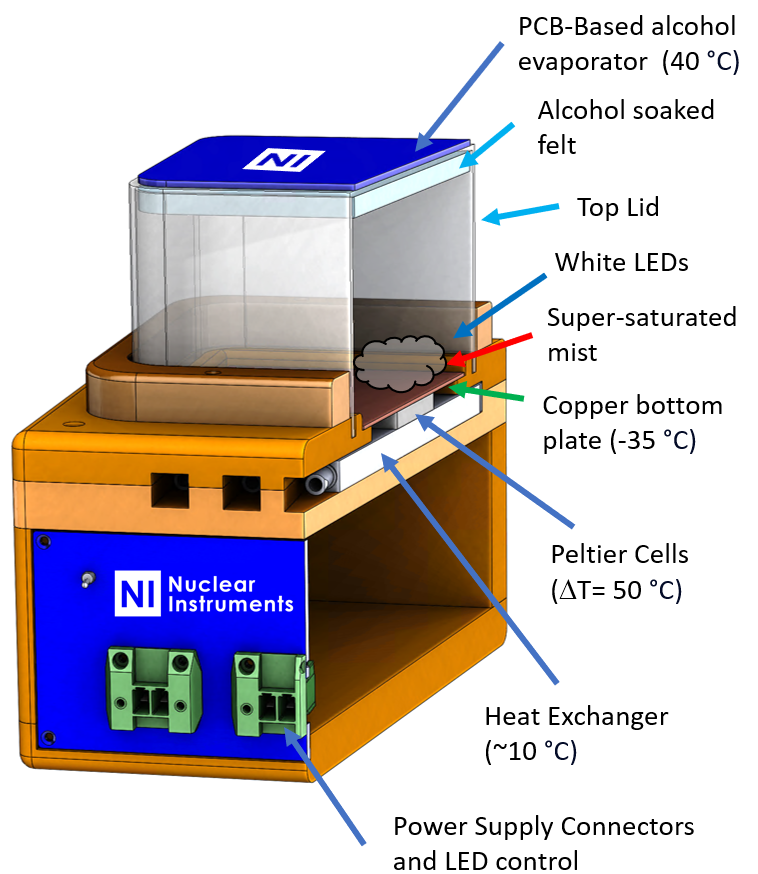

Section view of the chamber. The Peltier cells are mounted on the base plate, and the alcohol-air mixture is visible in the chamber.

Section view of the chamber. The Peltier cells are mounted on the base plate, and the alcohol-air mixture is visible in the chamber.

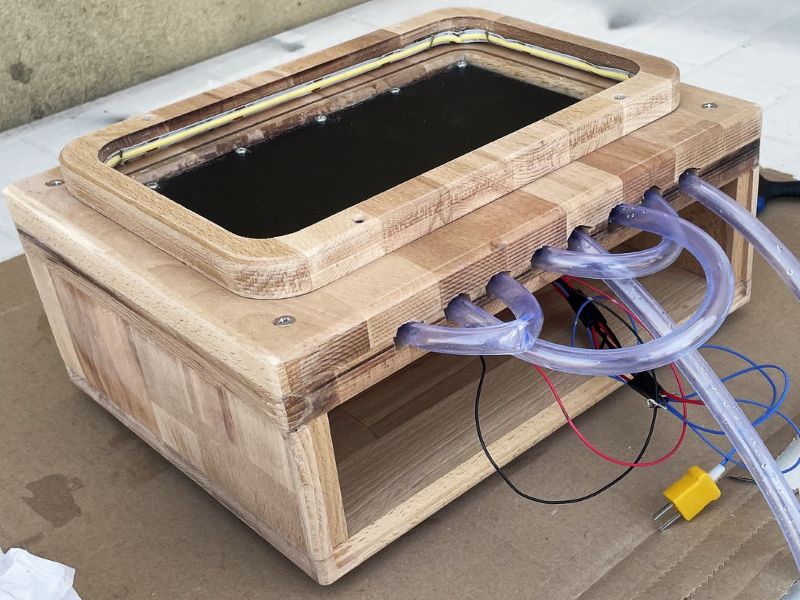

Picture while CNC milling the wood bottom heat exchanger holder.

Picture while CNC milling the wood bottom heat exchanger holder.

Bottom and top holder during the water-based painting process.

Bottom and top holder during the water-based painting process.

Picture of the gluing process of the bottom holder connector cover.

Picture of the gluing process of the bottom holder connector cover.

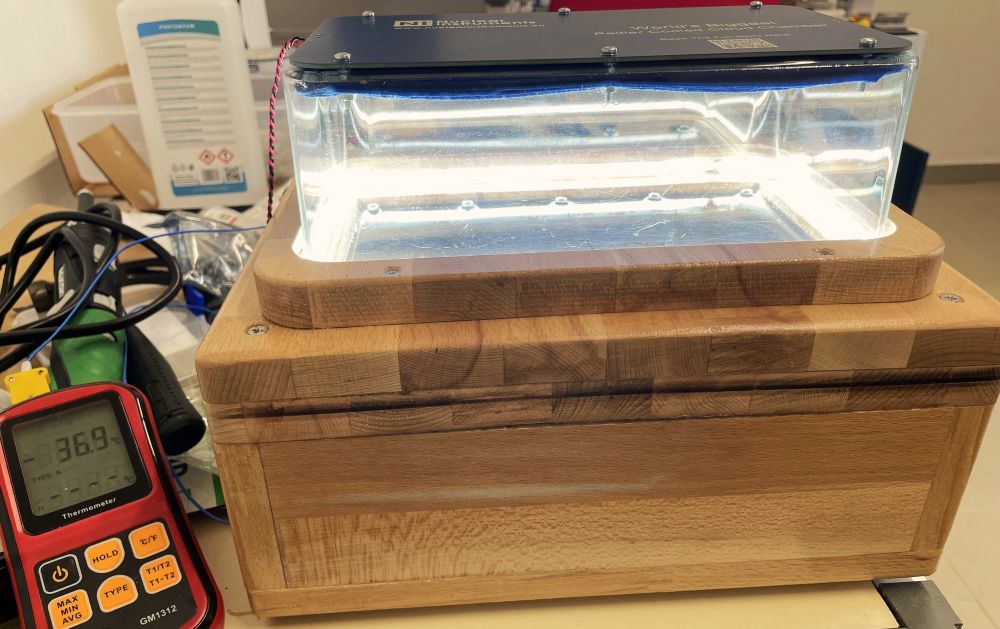

Test of the copper plate temperature before adding IPA.

Test of the copper plate temperature before adding IPA.

Cooling System: Reaching -35 °C Without Cryogenics

Achieving the necessary temperature gradient is the key engineering challenge. Alcohol vapor condenses at very low temperatures — typically below -30 °C. To reach and maintain these temperatures, we use four double-stage Peltier thermoelectric cells. These are solid-state devices that pump heat from one side to the other when powered by electricity.

Each double-stage cell is carefully mounted on a heat-conductive copper plate at the base of the chamber. The cells are arranged to maximize thermal uniformity across the surface.

With this configuration, we consistently cool the alcohol-air mixture to around -35 °C, which is optimal for track formation.

Construction Details

-

Chamber walls: Made of clear acrylic for full visibility and insulation.

-

Base plate: A thick copper plate ensures even temperature distribution.

-

Lighting: LED strip lights at an angle enhance visibility of the condensation trails without heating