Description

Introduction

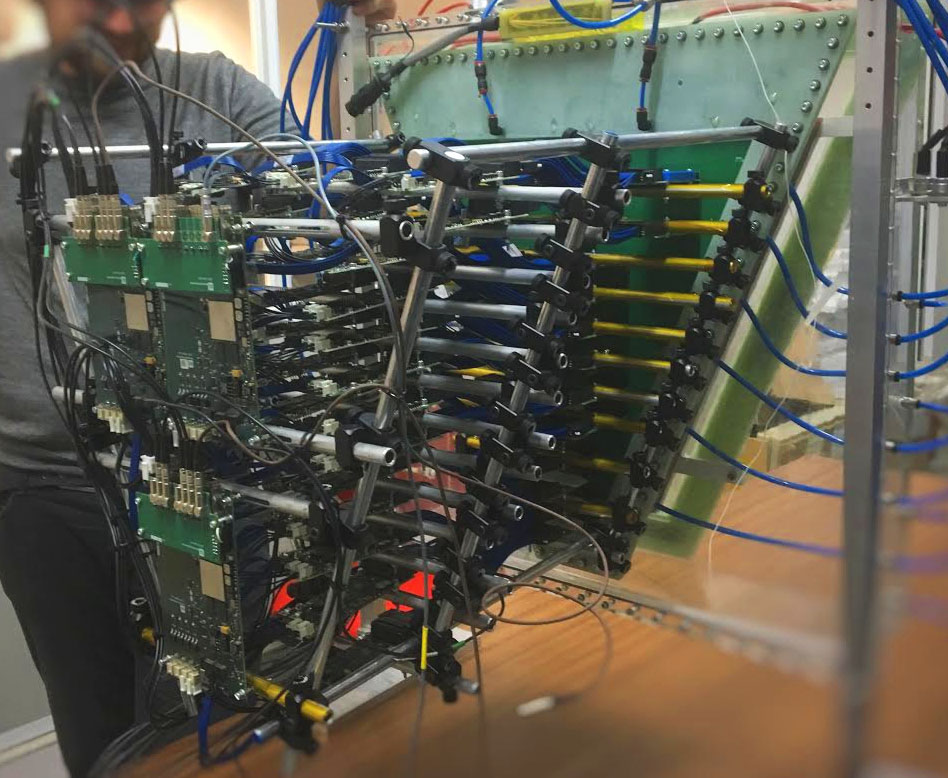

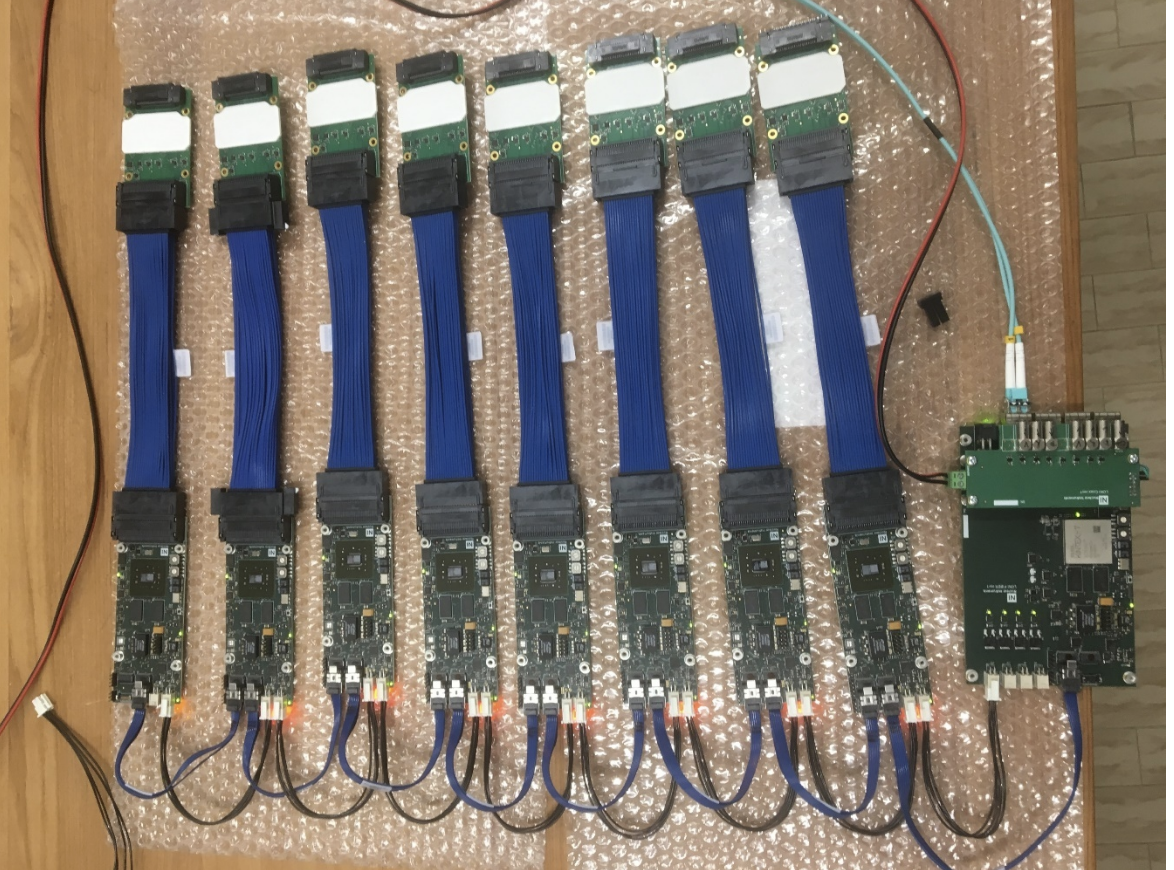

The system is designed to operate in high number of channels detector and offer scalability from 64 up to 100k channels detectors.

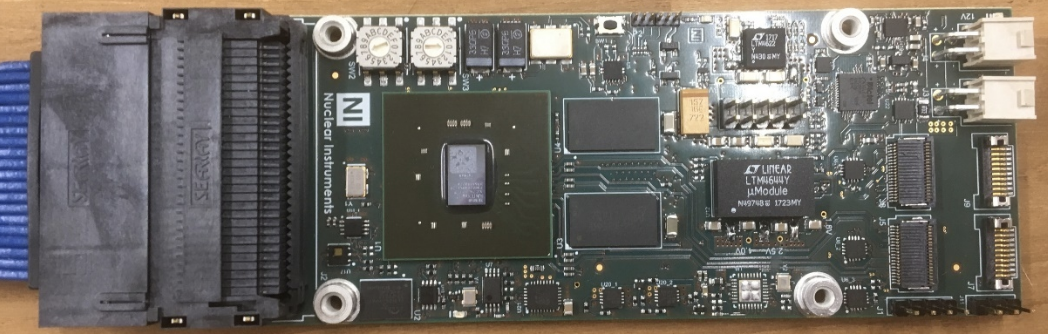

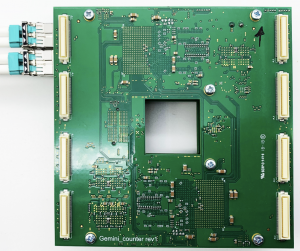

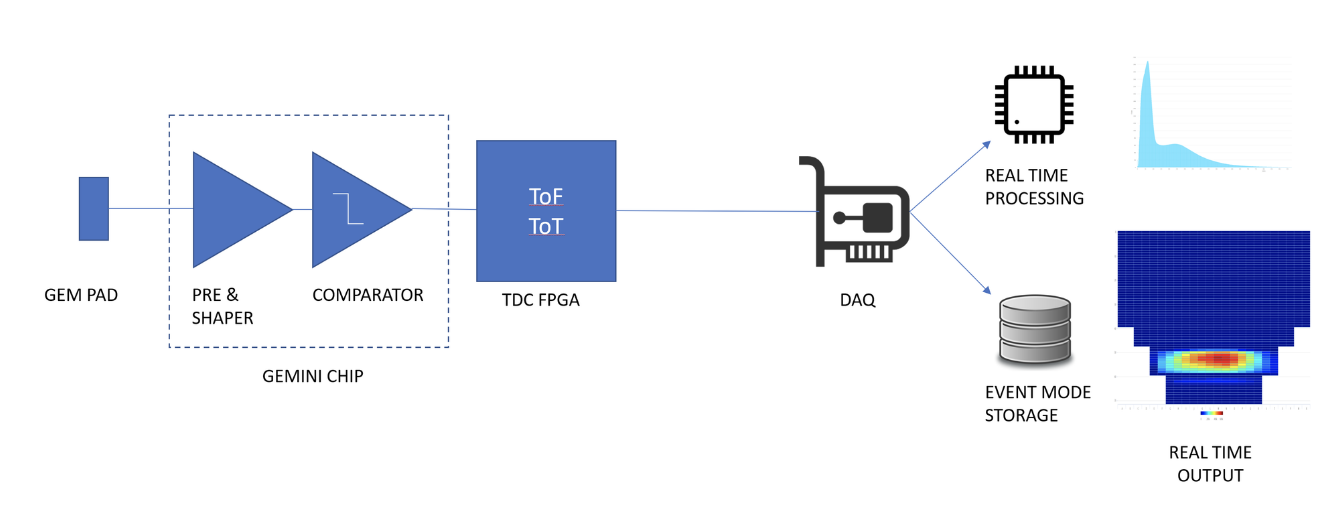

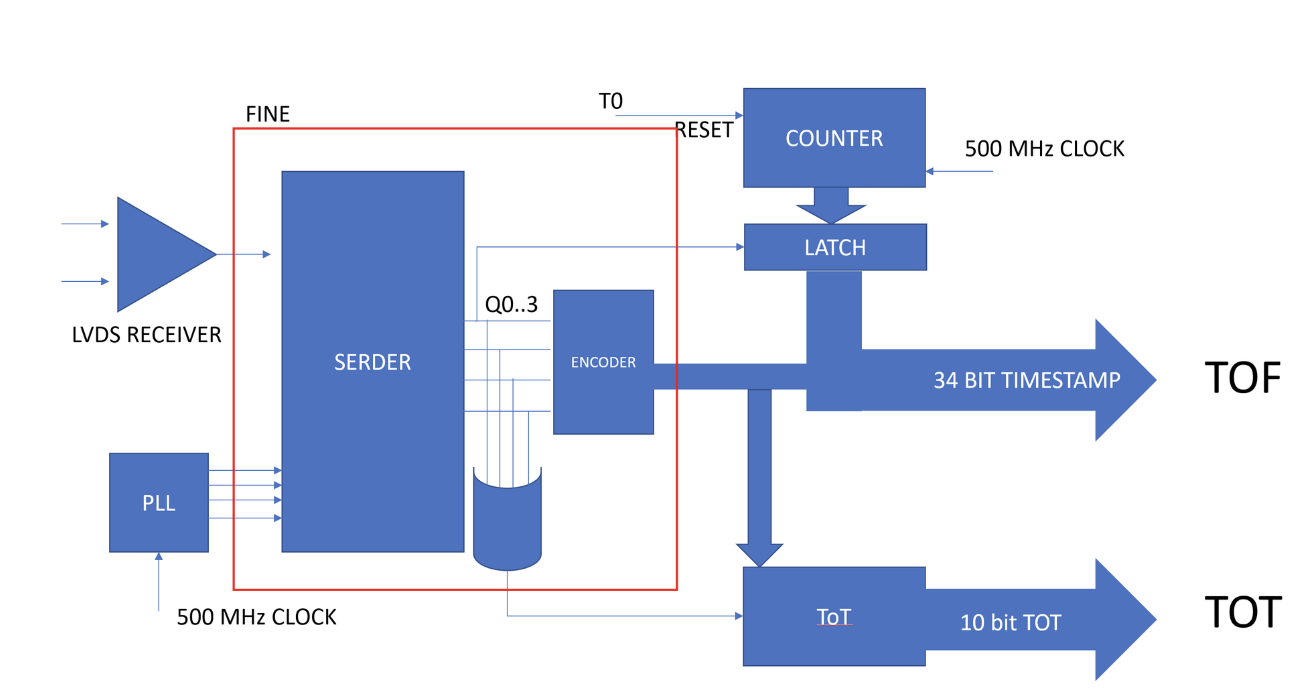

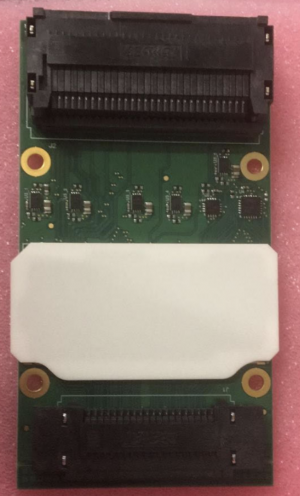

The system allows to readout GEM detector using GEMINI Asic, available on 64D (64 channels, digital output) board. The system implement a 64 channels TDC on a fpga system. The TDC has a resolution on 0.5 ns and allows to perform both ToF (time of flight) and ToT measures symultaneusly.

The ASIC implement the analog front-end, the comparator, and the threshold regulation.

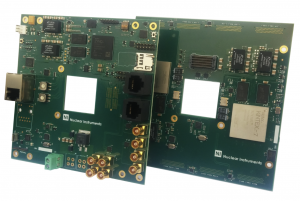

The FPGA board measure the ToF in respect to a T0 signal that can be generated inside the board or provided externally by a LEMO connector.

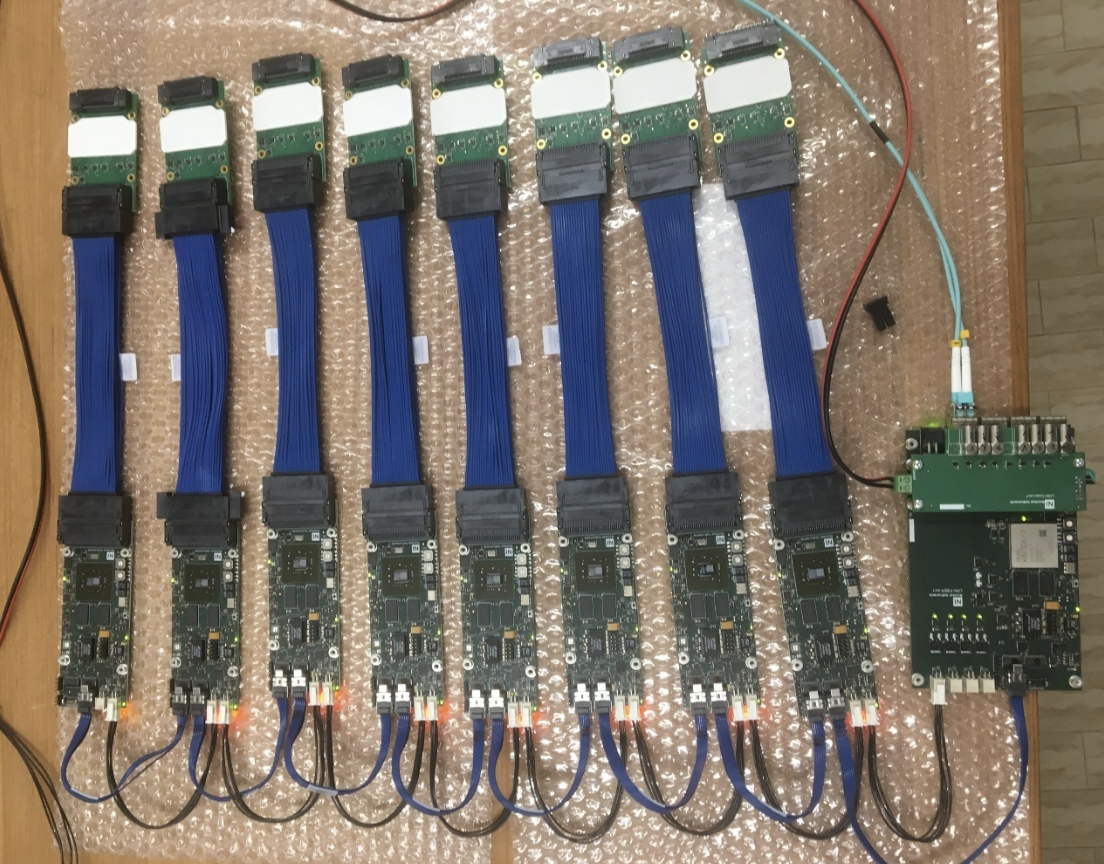

The FPGA board is interfaced to the readout PC using 10 Gbps optical link allowing a maximum readout speed of about 125 Mevent/s. The board can be daesy chained in order to increase the number of readout channels. Up to 126 board can be daesy chained on a single chain.

A PCIE board is installed in the readout PC in order to readout the data coming from the chain of boards. Each PCIE board can manage up to 4 chains and it is able to processs up to 600 Mevent/s offering a total bandwidth of 40 Gbps.

Multiple PCIE board can be installed in a single server

In order to off-load the CPU of the server, the FPGA on the PCIE board perform realtime reconstruction on the data in order to calculare the realtime monitor in hardware.

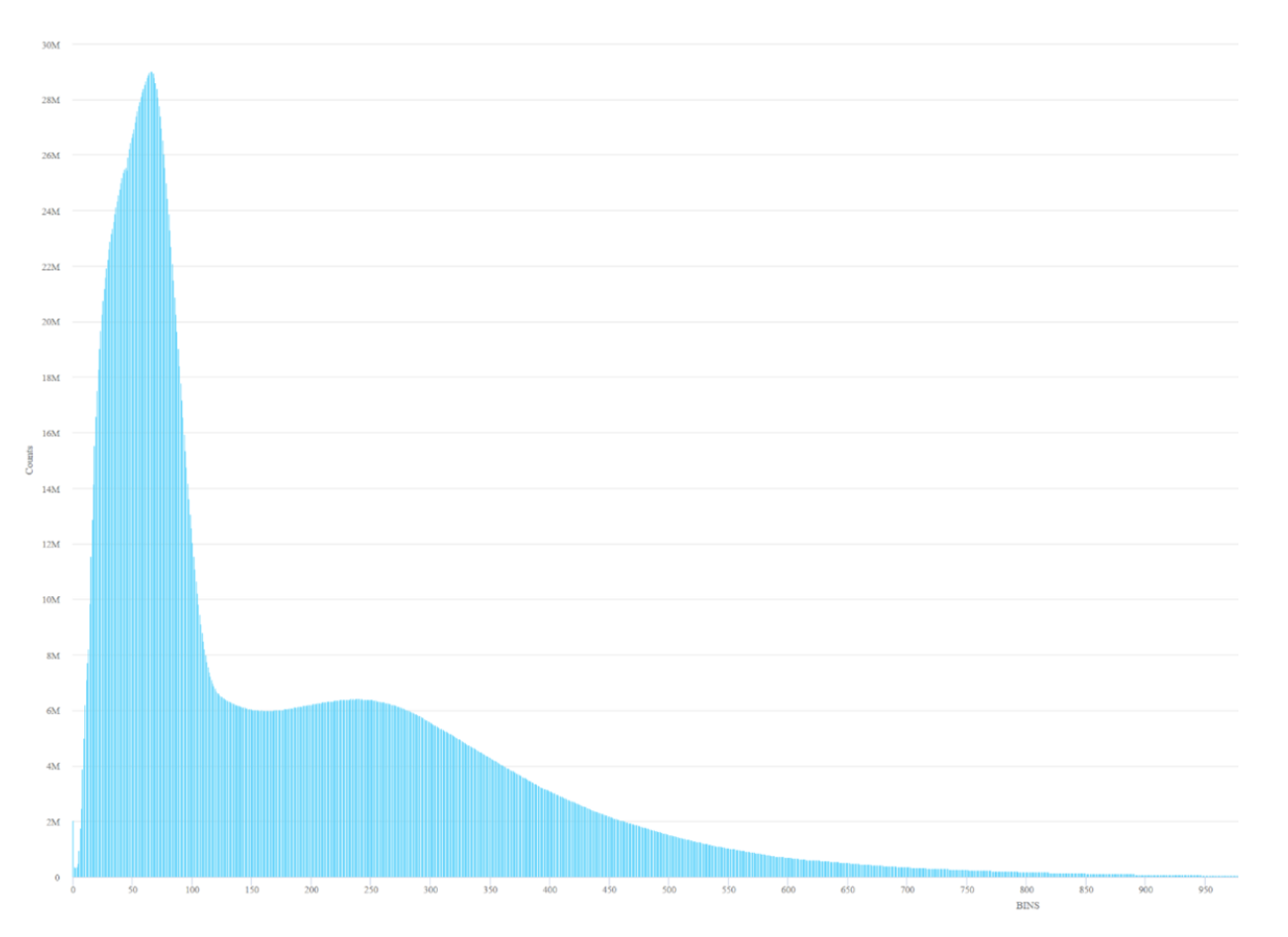

The ToT measure is proportional to the energy released by the interaction on the GEM detector, indeed it is possble to make spectroscopy measuraments or slice the 2D image in function of the energy

The readout is always performed in list mode. The software manipolate the list to extract information like Time Of Flight, energy spectrum, images, etc…

The FPGA board can be powered by a single 12v supply.

Highlighs:

64 pixel indipendently readout per board

Daesy chain solution: up to 126 board per chain

Time over threshold and time of flight measuraments.

64 TDC channels with 0.5 ns resolution

4ns double hit resolution

Up to 100 Mcps per chain

Up to 5 Mcps on single pixel (limited by the ASIC)

10 Gbps optical link per chain

Realtime monitor software with advanced analysys features

List mode data dumping

External (on lemo) and internal T0

External programmable VETO

Single channel programmable VETO

External busy output

PCIE readout board, 8x GEN 3, 40Gbps with realtime data processing in hardware

12V, 1.5 A

Linux server software

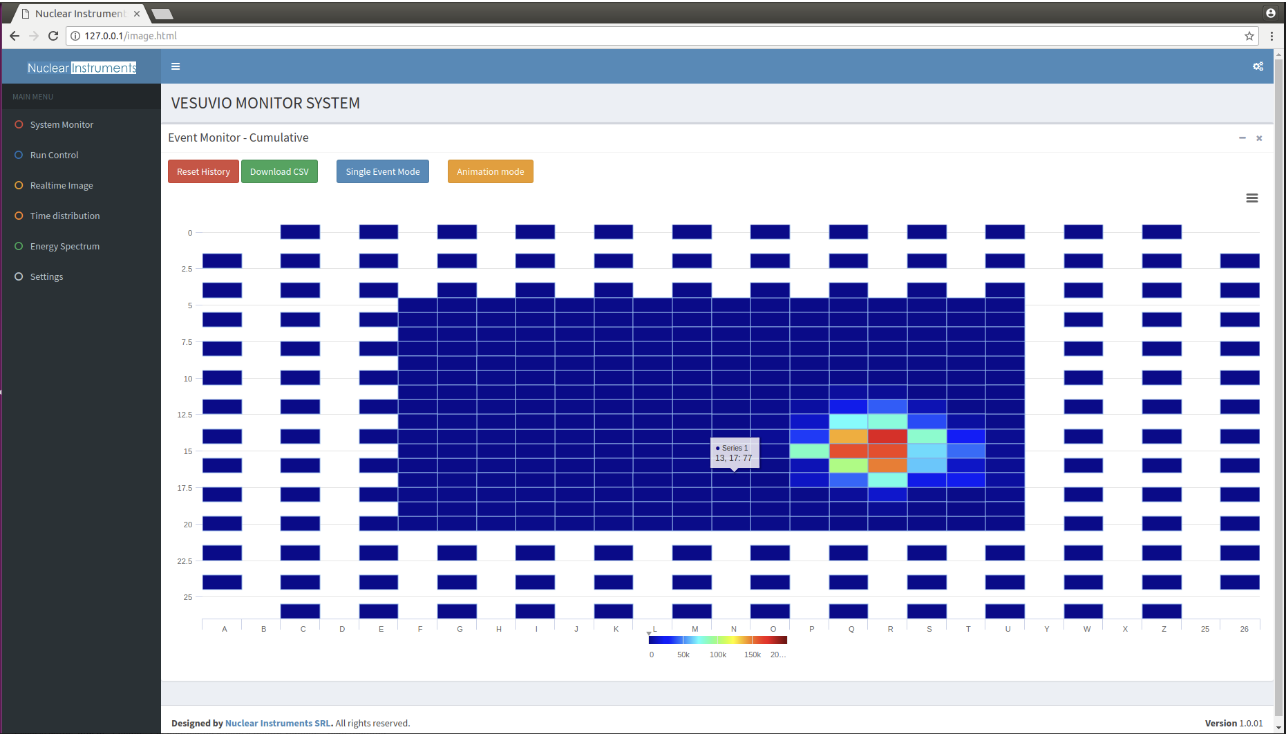

Web interface to control and monitor acquisition

Run database with API to interface the server DAQ with existing beam facility software

Software

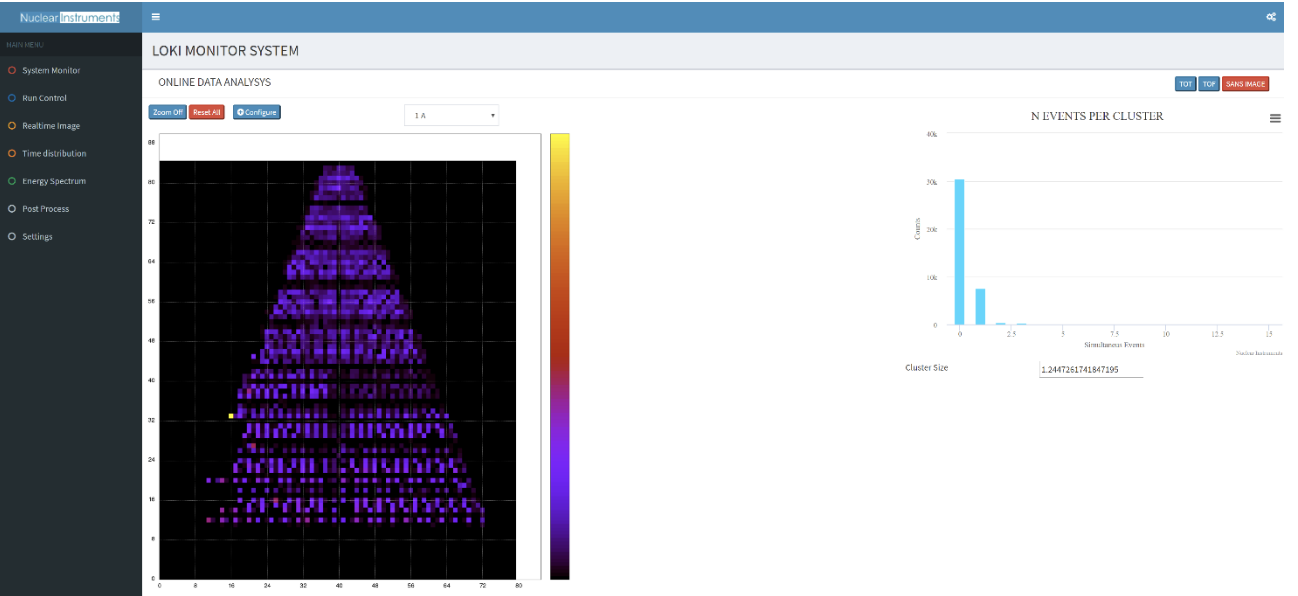

The software is based on a server side daemon and a client user interface. The acquisition daem runs on a linux server while the client webpage works on any modern broswer allows the configuration of managing of the system. All operation parameters of the ASIC (i.e. channel threashold, gain, veto) and DAQ parameters (like T0 source, T0 frequency, etc) can be configured by this interface.

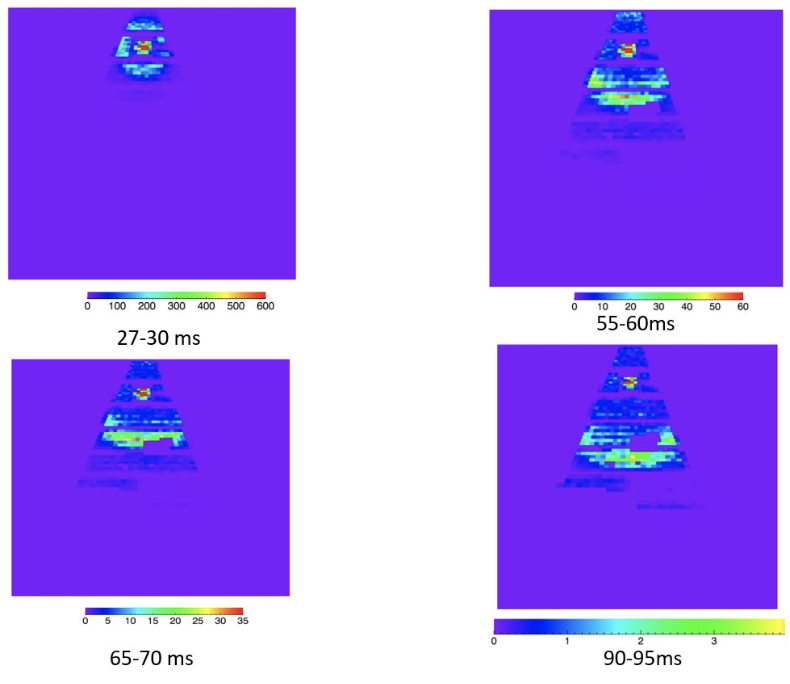

The software receive data from the FPGA and rencostruct in live, images and histograms. The software is capable to store data on disk in form of list while, at the same time, it perform live data processing.

The software is capable to perform the following online analysys:

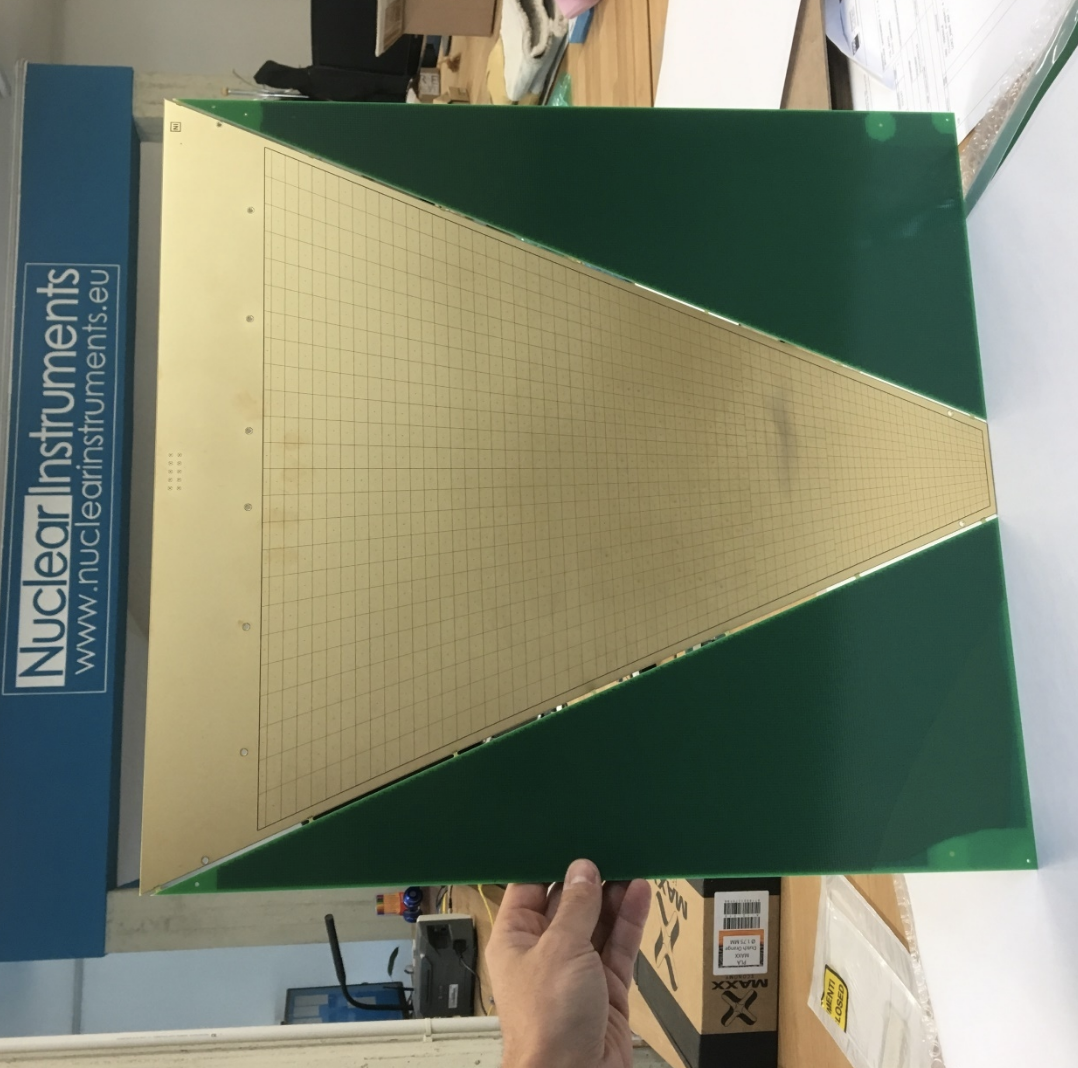

Image recostruction based on the pixel remap matrix that allows to readout any shape detector even if not rectangular

Display integral and realtime counts image

Display integral and realtime ToT image

Display images sliced by ToT

Display images slliced by ToF

Display TOF histogram for each channel

Display TOT histogram for each channel

Display TOT/TOF sum histogram applying calibration

Realtime calculation of statistic information like, input rate, T0 rate

The software include a MySQL based run database to store all runs information, including parameters like machine run, run current, type of run, and other custom parameters.

All data are stored server side and raw/processed data can be download via web interface.

An API interface in available to allows users to syncronyze the acquisition/the database with existing facilities software. The acquisition process can be totally controlled via API

The web interface include a slow control monitor that can be configure to collect information like HV status, detector temperature/humidity. It also allows to monitor the status of all boards providing information like link load, FPGA load, input/output rate, deadtime.

ASIC

In principle can be coupled with any asic capable to produce a TOT (time over threshold) LVDS or CMOS signal

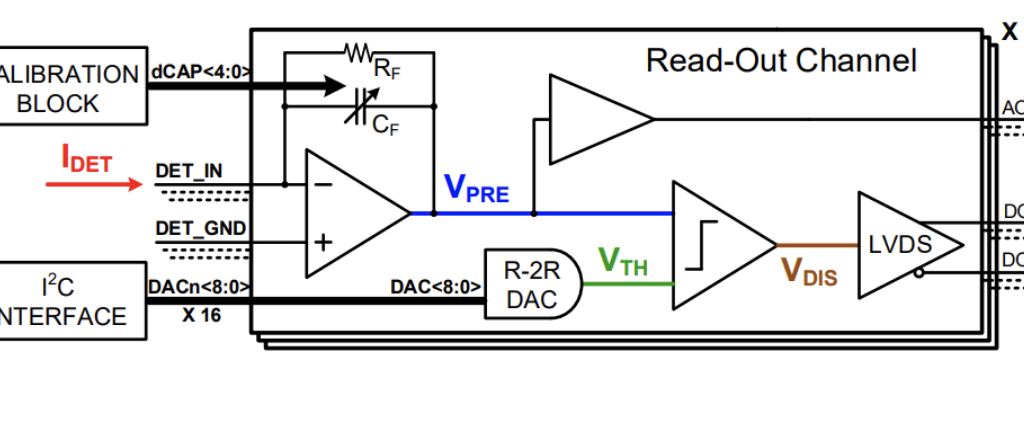

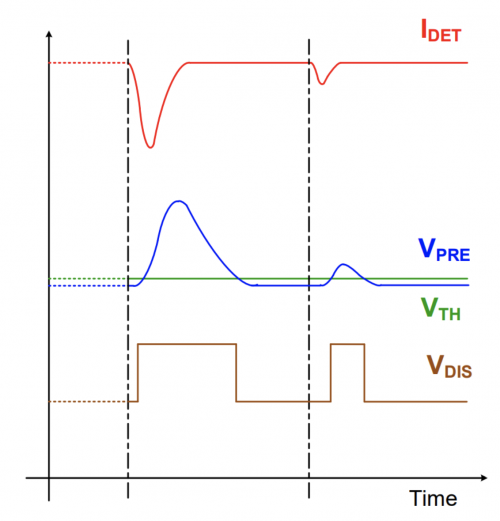

The system is designed to operate with GEMINI ASIC has been developed by the Microelectronic Group at University of Milano-Bicocca in collaboration with the IFP-CNR and the LNF INFN institutions. It has been thought to be dedicated to Triple GEM detector structures, but it can easily be re-adapted for detectors with similar performance. It is made of 16 detecting channels, each including a Charge Sensitive Preamplifier (CSP) with auto-tuned feedback capacitor and a Discriminator with a channel independent programmable threshold. The automatic calibration feature is provided in background by a dedicated unit, able to reach a feedback capacitor resolution less than 5%. The comparator programmable threshold is realized through the inclusion of a 9-bit R-2R Ladder DAC, with 1.2 mV LSB and 500 mV (or externally set) full-scale. The 9-bit threshold digital word can be set through an on-chip I2C interface, with dedicated registers. Two output signals for each channel are generated. The main output is digital. In fact, an LVDS signal is available for event counting rate up to 5 Mcps. In addition, making off-chip spectroscopy measures or checking the detector signal is possible via the analog CSP output.

In Figure the GEMINI read-out scheme is depicted, together with a channel main signals example plot. The SoC is made of 16 channels where, with the inclusion of a Charge-Sensitive Preamplifier (CSP), the signal from the detector is converted from charge domain to voltage domain. Then, the Discriminator (DISC) compares the CSP output voltage level with a threshold, set by an R-2R Resistive DAC and specific for each detecting channel, generating the Event Detection output signal. This output is then converted into LVDS standard through a dedicated driver. The channel also produces an analog output signal, which is the buffered CSP output.

Contribution

Nuclear Instruments is developing a detector based on large area scintillators to be placed underneath the drone. The first tests were carried out on 9 July using a digital inspector with 18x18x30 mm scintillator crystal.

The tests have shown that the scintillator + SiPM solution allows the identification of radioisotopes, in particular the presence of a potassium source, dispersed inside potassium chloride bags.

The Charge-Sensitive Preamplifier

The CSP composes of a Single Stage Telescopic Operational Amplifier (Opamp) with the CF capacitor and the RF resistor connected in feedback. The Q-V Gain imposed by specifications, i.e. 1 mV/fC, sets directly CF to 1 pF. With a 40 pF CD (pixel capacitance) maximum value, dimensioning the Opamp to obtain 58 dB DC-Gain and 80 µVRMS of in-band integrated noise means that the Signal-to-NoiseRatio lies in a range between 19 dB and 43 dB, with minimum (30 fC) and maximum (500 fC) charge respectively, while the charge collection efficiency is 98%.

The Discriminator

As regards the DISC, the main target is to reduce the input stage offset, in order to achieve the sensitivity and the detection jitter required (3 fC and 9 ns respectively). This means that the maximum tolerated offset is 3 mV after the CSP conversion, as well as for the R-2R Resistive DAC LSB, representing the minimum threshold. Designing the DISC with a mirrored structure and exploiting the inter-digitated layout technique allows to limit the offset within specs. Dealing with the threshold, the 9-bit R-2R Resistive DAC has a 1.2 mV LSB and 500 mV full-scale, set from the external. The input digital words, independent for each channel, are stored into dedicated registers managed from the I2C interface.

Example Application: